Recognizing the Performance of an Optical Fibre Diameter Analyser in Modern Manufacturing

The optical Fibre Diameter analyser serves as a pivotal instrument in modern production, supplying precise, non-contact measurements that are vital for preserving strict market standards. By leveraging sophisticated laser innovation, these analysers not just ensure minimal signal loss however additionally improve the general efficiency of optical fibers. Their capacity for real-time data processing enables producers to quickly attend to any deviations from specifications, fostering a culture of continuous improvement. Recognizing the intricacies of this modern technology raises questions concerning its wider ramifications in making effectiveness and quality assurance across numerous sectors.

Relevance of Optical Fibre Measurement

In modern production, the measurement of optical Fibre Diameter is vital for guaranteeing the efficiency and dependability of Fibre optic systems. Accurate Diameter measurement straight affects optical performance, as variations can lead to increased signal loss, lowered data transfer, and lessened overall efficiency. The optical residential properties, consisting of light transmission and signal honesty, are very delicate to the Fibre's Diameter, demanding exact control throughout production.

In addition, standardization in Fibre Diameter is crucial for compatibility and interoperability within varied telecoms networks. As these networks expand around the world, keeping harmony in Fibre characteristics advertises seamless assimilation across different parts and systems. Furthermore, sticking to sector standards concerning Diameter tolerances is important for makers to satisfy regulatory requirements and consumer assumptions.

Buying innovative dimension innovations not just improves manufacturing performance however likewise sustains high quality guarantee processes, enabling producers to identify issues early in manufacturing. This proactive technique minimizes waste and ensures that the last items satisfy rigid efficiency standards. The value of optical Fibre measurement can not be overstated, as it serves as a foundation for high-grade, reputable Fibre optic systems, which are important to modern interaction infrastructure.

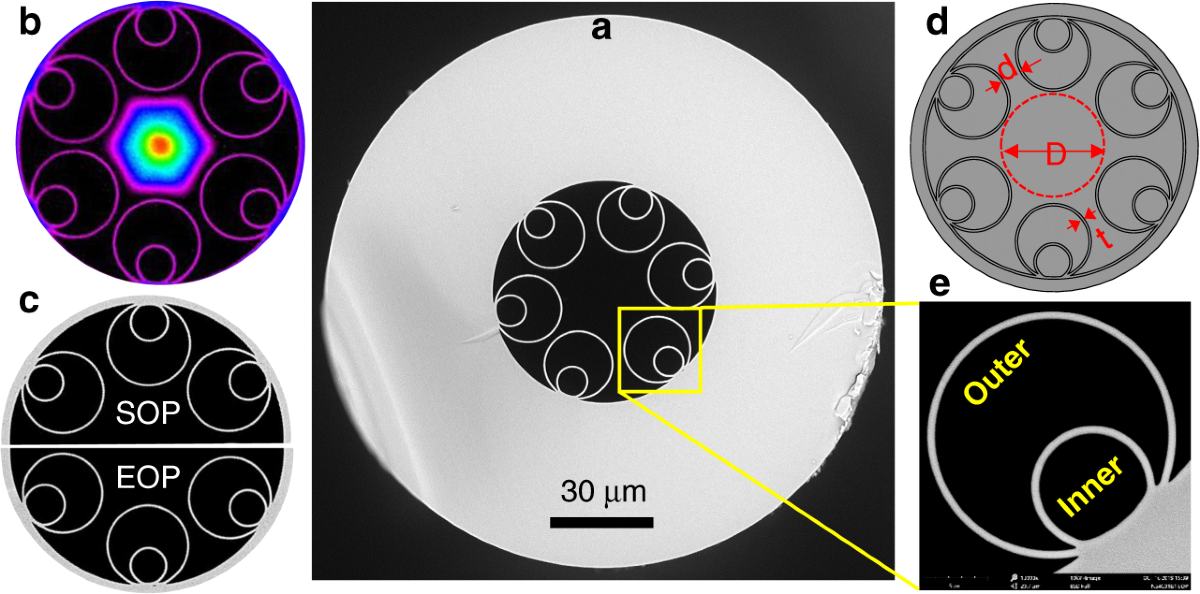

Just How Diameter Analysers Job

The core operation counts on the concept of light spreading and reflection. As the laser light beam strikes the Fibre, variations in Diameter cause changes in the light's intensity and wavelength (optical fibre diameter analyser). This data is processed in real-time using innovative algorithms that equate the optical signals into precise Diameter measurements

Furthermore, lots of Diameter analysers are outfitted with multiple dimension factors along the Fibre, permitting for a comprehensive assessment of Diameter uniformity. The implementation of such innovation substantially improves quality control in production, making certain that optical fibers are generated to exact specifications for ideal performance in their intended applications.

Secret Attributes to Consider

When choosing an optical Fibre Diameter analyser, numerous crucial functions warrant careful consideration to make certain optimum efficiency and reliability. Dimension precision is vital; the analyser should provide precise Diameter readings, normally in micrometers, to satisfy rigorous manufacturing specifications. Additionally, a broad dimension array improves flexibility, suiting different Fibre kinds and thicknesses.

An additional crucial attribute is the analyser's speed. Quick measurement official source capabilities enable raised throughput, necessary in high-volume production atmospheres. Additionally, real-time information handling and comments capacities enable instant blog modifications, improving top quality control.

Interface and software application compatibility are additionally significant considerations. A straightforward user interface streamlines operation, while robust software program support promotes information analysis and integration with existing production systems. The capability to export information in different styles can boost coverage and conformity efforts.

Additionally, resilience and maintenance demands need to be reviewed. An analyser constructed from premium materials will certainly endure the rigours of a production setting, while ease of maintenance ensures longevity and decreases downtime. Consider the degree of technical assistance and training offered by the manufacturer, as this can significantly affect the effective usage of the analyser in manufacturing settings.

Benefits in Production Performance

Enhancing manufacturing performance pivots on the combination of advanced innovations, such as optical Fibre Diameter analysers. These instruments play a pivotal function in making sure that optical fibers fulfill rigid quality requirements, which is crucial for ideal efficiency in numerous applications - optical fibre diameter analyser. By giving real-time measurements of Fibre Diameter, suppliers can promptly recognize and correct variances from specified tolerances, thus lowering waste and reducing the risk of malfunctioning items

Furthermore, the early discovery of possible problems causes minimized downtime and maintenance prices, thus enhancing resource allocation. Inevitably, the efficiency obtains recognized through using optical Fibre Diameter analysers add to a more competitive production environment, ensuring that firms can deliver top notch products while maintaining cost-effectiveness and responsiveness to market demands.

Applications Throughout Industries

The adaptability of optical Fibre Diameter analysers expands past making performance, finding applications across different markets that depend on optical Fibre technology. In telecoms, these analysers are critical for ensuring the ideal efficiency of Fibre optic cords, directly impacting information transmission rates and network integrity. By precisely gauging Fibre diameters, operators can decrease signal loss and enhance general communication high quality.

The clinical sector likewise profits dramatically from these gadgets, especially in the growth of endoscopic devices and laser treatments. Precise Diameter dimensions are vital for creating effective optical fibres that are made use of in minimally invasive procedures, boosting person results through boosted imaging and therapy capacities.

In aerospace, the analysers play a vital role in the production of light-weight, high-strength materials, where Fibre optics are integrated right into structural components for monitoring and diagnostics. In addition, the automotive sector utilizes these tools to make certain the honesty of Fibre optic sensors that boost safety read the full info here and security and performance functions in automobiles.

Verdict

In final thought, the optical Fibre Diameter analyser is crucial for modern manufacturing, making certain accurate dimensions that maintain market requirements. The diverse applications throughout different industries underscore the analyser's importance in advertising constant enhancement and data-driven decision-making within the manufacturing market.

In modern-day production, the measurement of optical Fibre Diameter is crucial for ensuring the performance and reliability of Fibre optic systems. The relevance of optical Fibre measurement can not be overemphasized, as it serves as a structure for high-grade, reputable Fibre optic systems, which are indispensable to contemporary communication framework.

Diameter analysers use sophisticated optical modern technologies to precisely gauge the Diameter of optical fibers.Furthermore, several Diameter analysers are furnished with multiple dimension factors along the Fibre, allowing for a detailed analysis of Diameter consistency.The flexibility of optical Fibre Diameter analysers prolongs past making performance, finding applications across various markets that depend on optical Fibre modern technology.

Comments on “Cutting-Edge Technology: The Optical Fibre Diameter Analyser and Its Impact on the Industry”